CONDENSED PHASE EXPERIMENTS

- Single Disc Holder for Transmission

- N2ITRO - Near Normal Incidence Transmission and Reflection Optics

- Cryogen-cooled Cryostats

- Grazing Incidence Angle (GIA)

SAMPLES

Typical condensed phase experiments at the Australian Synchrotron Far IR & HR beamline utilise the wide spectral range and high intensity of the synchrotron source. Condensed phase samples can be supported/mounted for analysis in a number of different ways.

Single Disc Holder for Transmission

For the study of samples that can be pressed into disks or pellets 13 mm in diameter (see Sample Types). Note that a pellet press is available in the Chemistry Laboratory. Please inform IR Beamline staff if you require access to this instrument to press your samples.

N2ITRO - Near Normal Incidence Transmission and Reflection Optics

|

|

|

N2ITRO |

Optical path of N2ITRO |

Features

- Fixed angle of incidence: 11°

- Unit can be switched computer controlled in order to measure the same sample position in transmission and reflection mode, without breaking vacuum

- Includes OPUS macro for automated measurement procedure

- Polarizer assembly with automatic rotation

Cryogen-cooled Cryostats

We currently have two cryostats, for discs 13 mm in diameter. Ideal for the study of phonon modes in cryogenically-cooled crystals. We have a Janis research cryostat and a Closed loop, Pulsed tube Cryostat from Cryo Industries.

The Janis system has 3 sample positions and is generally used at liquid nitrogen temperatures.

The Cryo Industries system has four sample positions and is designed for use at near liquid helium temperatures.

Grazing Incidence Angle (GIA)

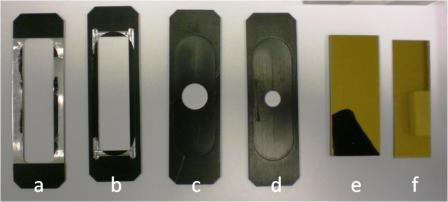

For the study of thin films or monolayers. Ideally samples should be uniformly deposited on a gold- or aluminium-coated microscope slides, 3“x1” in size, however sample masks are available for irregular sized samples (see figure 14). Contact IR Beamline staff for more information. The grazing angle of incidence can be varied between 30° and 80° in 1° increments.

Condensed Phase Sample Types

Optical Sample Support Material

- Potassium bromide (KBr) > 400 cm-1

- Polyethylene (PE) < 400 cm-1 Two particle sizes, 150μm and 30μm are available, please discuss with your beamline scientist your requirements.

- TPX < 200 cm-1

- Quartz < 200 cm-1

Crystals/Particulates

- The suggested experimental method for you requires you to press your sample into pellets.

Grazing Incidence Angle Cell

- For thin films

- Typically samples are coated on gold- or aluminium-coated microscope slides, 3“x1” size, however smaller sized samples can be accomodated (see figure 14)

Self-supported Samples

- The sample must be suitable to mount to an appropriate accessory

Pressing pellets for far-IR spectroscopy

Make sure you bring blank discs or discs made of your supporting material only (no sample) to use as references/backgrounds

What you need |

Where to find it |

|

Sample |

User supplied |

|

Pellet powder |

User supplied, some available at the beamline, but in limited amounts, and only after previous arrangements have been made with the beamline scientist |

|

Die Set |

At the beamline, may be heated, or evacuated for advanced sample preparation |

|

Mortar and pestle |

Beamline, some may be available in Chemistry Lab |

|

Scales/Small weigh boats |

Chemistry Lab |

|

Pellet Press |

Chemistry Lab |

Preparing the powder for KBr Pellets (Mid-IR 400-33000 cm-1)

The amount of sample you require depends on the sample itself and how much it absorbs in the far-IR. As a rough guide 15mg per sample with 30-50 mg of KBr powder is normal. But I stress that it is sample dependant. The powder sample and KBr must be ground to reduce the particle size to less than 5 mm in diameter. Otherwise, large particles scatter the infrared beam and cause a slope baseline of spectrum.

KBr is hygroscopic so make sure to put the powder back in the dessicator at the beamline when finished.

A typical pressure and pressing time for KBr is 9 tons for 10 minutes.

Preparing the powder for PE Pellets (10-600 cm-1)

As with KBr, the amount of sample you require depends on the sample itself and how much it absorbs in the far-IR. As a rough guide 15mg per sample with 30-50 mg of PE powder is normal. But I stress that it is sample dependant. You would get the best results if you can press the pellet entirely out of sample (~50mg) but usually the sample doesn’t bind enough to make a pellet, or it absorbs too strongly in the IR. If it is a strong absorber, then you might be able to use only a few mg of sample per pellet.

A typical pressure and pressing time for PE is 8 tons for 10 minutes

Pressing the pellets:

Ascertain the amount of quantity of powder you need to prepare your sample.

Place some labmat bench protector on the bench and arrange the die set composed by the following items:

The body with a detachable base, a plunger, and two polished steel anvils/pellets (please be aware that these pellets have two different sides; (only the polished side should be kept in contact with the sample).

Put the die set on the press and press for desired time.

Advanced pellet pressing:

In some cases you might want to try heating your pellet, or the die. There is access to both an oven and a furnace in the chemistry laboratory. Please make sure you remove any o-rings before heating the die. For PE the melting point is around 105-120 up to 180, please make sure your samples can withstand this kind of temperature.

Please consult your beamline scientist before using this equipment. Training is required.

There is a glovebox located in the chemistry laboratory that can be purged with nitrogen or other kinds of gas, for samples sensitive to air.

The dies can also be evacuated. This produces a more even pellet.

A hand press is avbailable with 1mm, 3mm and 7mm dies. Use of the small pellet size is usually required when large amount of samples are difficult to come by - because they are expensive materials, or materials that are difficult to synthesize; using this technique/approach with pure samples has the advantage of avoiding optical effects due to the binding material and the added advantage of sample recovery.