They can also be integrated with specific catalysts in a single ‘membrane reactor’ that combines several processes into one, and allows the equilibrium barrier of some reactions to be broken by continuously removing H2 gas from the system. In the case of natural gas reforming, this enables complete conversion at 550°C rather than the 800°C required in a non-membrane reactor.

Palladium alloy membranes are the current benchmark in alloy membrane technology, but their high cost is a severe limitation, particularly given the US Department of Energy’s 2015 cost target of around US$1000 per square metre.

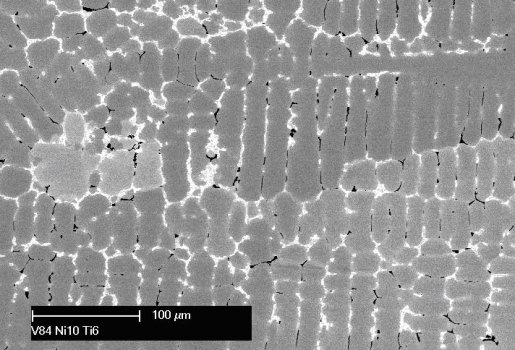

Michael Dolan from CSIRO Energy Technology is developing vanadium alloy membranes that cost less than their palladium counterparts. Vanadium’s higher hydrogen absorption and permeability values also potentially offer better performance. Michael says the market potential of the new membranes is “vast”.

A major challenge is that absorption of hydrogen into the alloy membrane material fundamentally changes the physical properties of the host metal, leading to reduced strength, phase instability and expansion. These must be managed by tailoring the alloy composition or the operating conditions, or both, to ensure high performance, durability and low cost.

Michael and his colleagues are using in-situ x-ray powder diffraction at the AS to investigate how temperatures up to 400°C and various hydrogen gas pressures affect hydrogen-induced lattice expansion, which can create significant stresses that need to be accommodated. They’re also looking at the formation of ordered hydride phases, a phenomenon that can lead to eventual mechanical failure. Operating regimes for vanadium alloy membranes must be designed to avoid hydride formation.

Michael and his colleagues are using in-situ x-ray powder diffraction at the AS to investigate how temperatures up to 400°C and various hydrogen gas pressures affect hydrogen-induced lattice expansion, which can create significant stresses that need to be accommodated. They’re also looking at the formation of ordered hydride phases, a phenomenon that can lead to eventual mechanical failure. Operating regimes for vanadium alloy membranes must be designed to avoid hydride formation.

The researchers use in-situ neutron and synchrotron x-ray diffraction techniques to study how their materials behave, including the formation of defects and stresses within the membranes as a result of hydrogen transfer. In-situ analysis is the only way to observe the membrane microstructure under the dynamic conditions of a hydrogen permeation test. The synchrotron is essential for studying vanadium-based alloys because vanadium is a very poor scatterer of neutrons, and because laboratory x-ray sources cannot provide the high resolution and rapid data collection required.

Michael says CSIRO is also working to develop a manufacturing process for defect-free tubular alloy membranes, produce full-size membrane reactors for gasification and reforming reactions, and use solar energy to supply the heat required for the process. The group hopes to progress to pilot-scale trials with commercial partners when the current research program ends in 2015.

Three images above: all courtesy of Keith McLennan, CSIRO

Above right, top:close-up of membrane materials

Above right, middle: the CSIRO membrane team in the powder diffraction user cabin

Image above left: micrograph of one of the membrane alloys tested by CSIRO